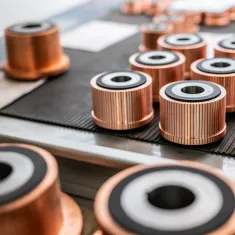

SUKaT molded commutators

Molded commutators with diameters of 40 - 400 mm for high circumferential speeds of 60 - 80 m/sec, highly thermally stressed - thermal resistance in class F and H - with high dimensional stability. Use for highly mechanically and thermally stressed motors in material handling equipment (forklift trucks) with a variant particularly suitable for traction motors.

Solution concept

The internal design is different from conventional designs of molded commutators. The anchoring of the blades into the support housing by means of herringbones with a tightly defined shape and position of the blades results in a structure that has a high radial stiffness and ensures high mechanical stability of the commutator's blade wreath. The relatively thin layer of moulding compound allows very good heat transfer between the lamellar wreath and the commutator housing.

Advantages of the solution

- High dimensional stability at extremely high peripheral speeds and elevated temperatures

- Large cross-section for cooling channels in the commutator housing independent of the commutator length

- High motor cooling efficiency

- High dimensional and dimensional accuracy

- High dimensional and dimensional accuracy

Technical data

- Laminated copper: CuAg 0.04 %, possibly 0.1 %, if required

- Laminated insulation: micanite, if required. as required

- Commutator housing: steel, version with or without ventilation holes of various designs

- Diameter range: 4 0 - 400 mm

- Axial length of the lamella: 25 - 250 mm

- Commutator in versions without or with flag part, with cut slots for conductors, with or without tin plating, or without slots

Commutators can be produced in large or small quantities, or in pieces, with low production preparation costs and short delivery times.

Download order form